FireResistant Siding Materials A Comprehensive Guide

FireResistant Siding Materials offer crucial protection against fire damage, significantly enhancing building safety. This guide delves into the diverse types of fire-resistant siding available, exploring their composition, performance characteristics, installation, maintenance, and cost-effectiveness. We’ll examine relevant building codes and regulations, discuss sustainable options, and showcase real-world applications to illustrate the impact of choosing the right fire-resistant siding for your project.

Understanding these factors empowers informed decision-making, leading to safer and more resilient structures.

From the robust durability of metal siding to the aesthetic appeal of fiber cement, the choices are varied and depend heavily on individual needs and budget. This guide aims to clarify the complexities surrounding fire-resistant siding, offering a practical resource for homeowners, builders, and architects alike. We will explore the intricacies of fire ratings, installation techniques, and long-term maintenance strategies to ensure the continued effectiveness of this crucial building material.

Types of Fire-Resistant Siding Materials: FireResistant Siding Materials

Choosing fire-resistant siding is a crucial aspect of building a safe and secure home. Several materials offer varying degrees of protection against fire, each with its own set of advantages and disadvantages. Understanding these differences is key to making an informed decision.

Fire-Resistant Siding Material Overview

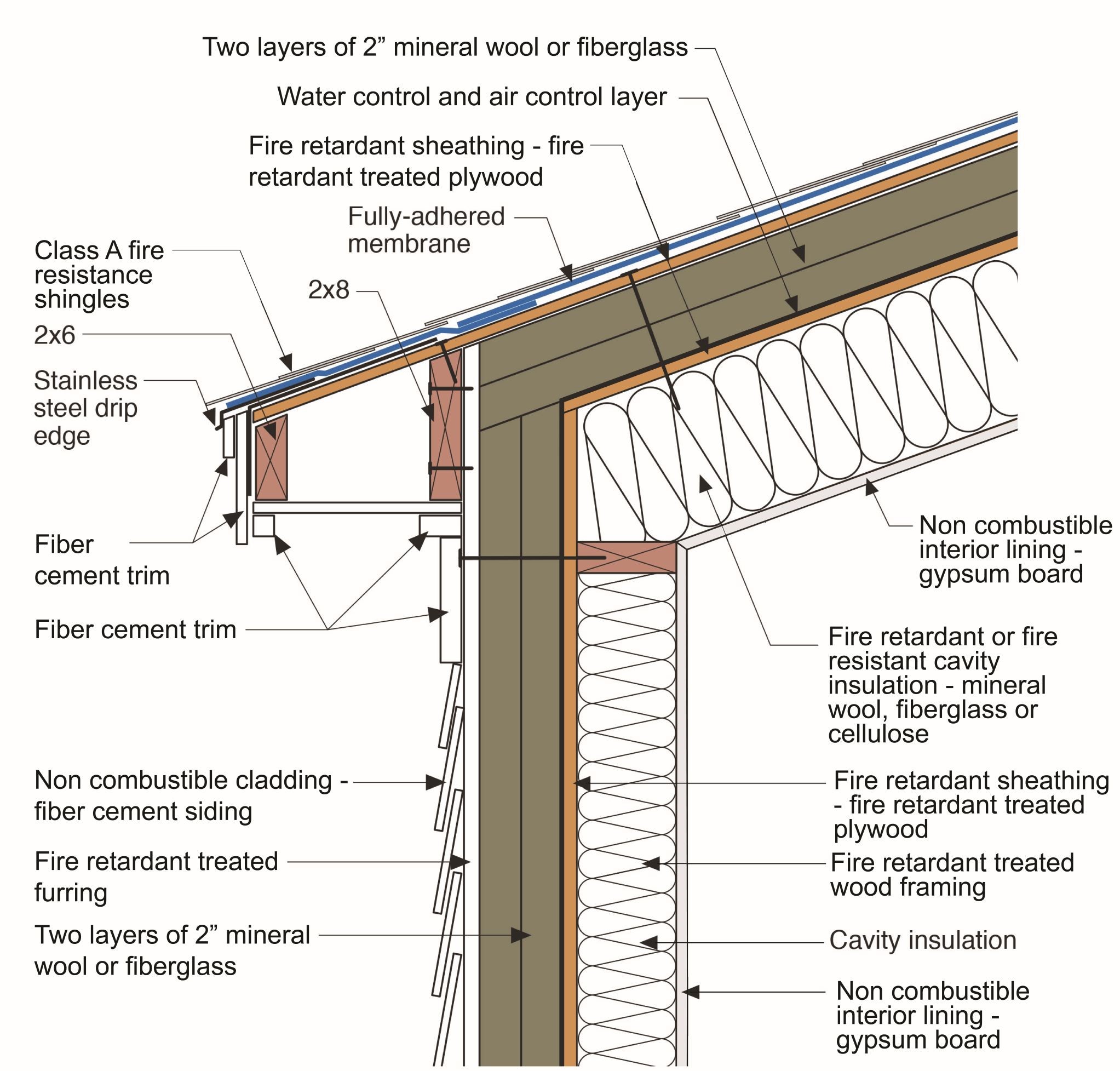

A range of materials provide excellent fire resistance for exterior siding. These include fiber cement, metal (such as aluminum or steel), and composite materials incorporating fire-retardant additives. The selection depends on factors such as budget, aesthetic preferences, and the specific fire safety requirements of the building codes in your region.

Chemical Composition and Manufacturing Processes

Fiber Cement Siding: This material is a composite of Portland cement, cellulose fibers (often wood pulp), and silica sand. The manufacturing process involves mixing these ingredients with water, forming them into sheets or panels under high pressure, and then curing them in a controlled environment. This process creates a dense, non-combustible material. The cellulose fibers provide tensile strength, while the cement acts as a binder and provides fire resistance.

The silica sand adds durability and resistance to weathering.

Metal Siding (Aluminum): Aluminum siding is made from rolled aluminum sheets. The manufacturing process involves alloying aluminum with other metals to enhance strength and corrosion resistance. The sheets are then coated with a protective layer, often a baked-on paint, to enhance durability and aesthetics. Aluminum’s inherent properties make it highly resistant to fire, primarily due to its high melting point.

Composite Siding (with fire-retardant additives): Composite siding often combines wood fibers or plastic polymers with fire-retardant chemicals. The manufacturing process involves mixing these components, molding them into the desired shapes, and then curing them under heat and pressure. The specific fire-retardant additives vary depending on the manufacturer and may include substances like borates or phosphates. These additives increase the material’s ignition resistance and limit the spread of flames.

Comparison of Fiber Cement, Metal, and Composite Siding

Fiber cement siding boasts excellent fire resistance, durability, and relatively low maintenance. However, it can be more expensive than other options and is susceptible to cracking if not installed properly. Metal siding, particularly aluminum, offers superior fire resistance and longevity, with minimal maintenance requirements. However, it can be more prone to dents and scratches than fiber cement. Composite siding provides a balance between cost and performance, but its fire resistance varies significantly depending on the specific additives used.

Regular maintenance is usually required to maintain its appearance and structural integrity.

Fire-Resistant Siding Material Characteristics

| Material | Fire Resistance Rating (varies by product and testing standards) | Cost (per square foot, approximate) | Lifespan (years) | Maintenance Requirements |

|---|---|---|---|---|

| Fiber Cement | Class A (generally) | $3-$8 | 30-50 | Periodic cleaning, occasional repainting |

| Aluminum | Class A | $2-$6 | 40-60 | Minimal, occasional cleaning |

| Composite (with fire retardants) | Class A or B (depending on additives and specific product) | $1.5-$5 | 15-30 | Regular cleaning, potential for repainting or replacement of damaged panels |

Fire Resistance Ratings and Standards

Understanding fire resistance ratings and standards is crucial for ensuring the safety and longevity of buildings. These ratings provide a quantifiable measure of a material’s ability to withstand fire, allowing architects, builders, and building code officials to make informed decisions about material selection. Different classification systems exist, each with its own methodology for assessing fire resistance. Compliance with relevant building codes is mandatory to guarantee structural integrity and occupant safety in the event of a fire.

Fire Resistance Rating Systems

Several systems classify the fire resistance of building materials, including siding. These systems typically consider factors like the time a material can resist fire’s effects (e.g., preventing the passage of flames or heat), its structural integrity under fire conditions, and its insulation properties. Common rating systems include those used in the United States, Canada, and Europe, each with its own specific standards and testing procedures.

For example, the ASTM E119 standard in the US provides a standardized test method for determining the fire resistance of building construction and materials. This test involves subjecting a specimen to a controlled fire exposure and assessing its performance based on pre-defined criteria. Similar standards exist internationally, though the specific requirements may vary.

Building Codes and Regulations

Building codes and regulations play a pivotal role in mandating the use of appropriate fire-resistant materials in construction. These codes vary by jurisdiction (national, state/provincial, and local levels) and are often updated to reflect advancements in building science and fire safety technology. For instance, the International Building Code (IBC) in the United States provides a model code widely adopted by many jurisdictions.

This code specifies minimum requirements for fire resistance based on factors such as building occupancy, height, and construction type. Local authorities may impose stricter regulations based on specific risk assessments or environmental considerations. Non-compliance can result in significant penalties, including project delays and legal ramifications.

Testing Methods for Fire Resistance

Determining the fire resistance of siding materials involves rigorous testing procedures, typically conducted in accredited laboratories. These tests subject the materials to controlled fire exposure for a specified duration, measuring various parameters such as temperature rise, flame spread, and structural integrity. The ASTM E119 standard, as mentioned earlier, is a widely recognized test method. The test involves constructing a wall section with the material under evaluation and exposing it to a standardized fire curve.

Observations are made at regular intervals to assess the material’s performance, leading to a classification based on the duration it resists the fire and maintains structural integrity. Other tests, like those assessing smoke generation and toxicity, may also be performed.

Flowchart for Selecting Fire-Resistant Siding

[A flowchart would be inserted here. The flowchart would visually represent the decision-making process. It would begin with identifying the building’s location and intended use. This would lead to referencing the applicable building codes and regulations. Next, the flowchart would show the selection of potential siding materials based on the code requirements.

Finally, the flowchart would conclude with verification that the chosen siding meets all the necessary fire resistance standards and local regulations.] The flowchart would utilize decision points (diamonds) to represent choices based on code requirements, and rectangular boxes to represent actions or steps in the selection process. The end result would be the selection of an appropriate fire-resistant siding material.

For example, a decision point might ask “Does the building code require a Class A fire rating?”, with branches leading to different material options based on a “yes” or “no” answer.

Installation and Maintenance of Fire-Resistant Siding

Proper installation and diligent maintenance are crucial for ensuring the longevity and fire-resistant properties of your siding. Neglecting either can significantly reduce its effectiveness and potentially compromise the safety of your property. This section details best practices for two common types of fire-resistant siding: fiber cement and metal.

Fiber Cement Siding Installation

Fiber cement siding offers excellent fire resistance and durability. Installation generally involves these steps:

- Preparation: Begin by ensuring the underlying wall sheathing is sound and free from damage. Properly install any necessary water barriers and flashing to prevent moisture intrusion, a factor that can weaken the siding over time and reduce its fire resistance.

- Framing and Furring Strips: Install vertical furring strips, spaced according to the manufacturer’s specifications, to create a ventilation gap behind the siding. This aids in moisture management and prevents the build-up of heat, both critical for maintaining fire resistance.

- Siding Installation: Starting at a corner, install the fiber cement panels, overlapping them according to the manufacturer’s instructions. Use appropriate fasteners and ensure they are driven straight to avoid cracking the panels. Proper fastening is essential for structural integrity and to maintain the fire-resistant properties.

- Caulking and Finishing: Apply caulk to seal gaps and joints between panels, preventing moisture penetration. Install trim and other finishing elements to complete the installation.

Metal Siding Installation

Metal siding, particularly aluminum or steel, is another popular choice for its fire resistance and low maintenance. Installation typically involves:

- Preparation: Similar to fiber cement, prepare the wall sheathing, ensuring it’s clean, dry, and structurally sound. Proper preparation is key to the longevity of the siding and its fire resistance.

- Framing: Install vertical or horizontal framing, depending on the siding design, to provide a stable base for the panels. The spacing will depend on the type and gauge of the metal siding used.

- Panel Installation: Begin at a corner or edge and install the metal panels, overlapping them according to the manufacturer’s instructions. Use self-tapping screws designed for metal siding and ensure they are driven at the correct depth to prevent damage to the panels. Over-tightening can cause warping and compromise the integrity of the installation.

- Sealing and Finishing: Seal any seams or joints with appropriate sealant to prevent moisture penetration. Install trim pieces to create a clean and finished look.

Maintenance of Fire-Resistant Siding

Regular maintenance is vital to preserving the fire-resistant qualities and extending the lifespan of your siding.

This includes:

- Regular Cleaning: Clean the siding annually using a soft brush, mild detergent, and water. This removes dirt, grime, and other debris that can accumulate and potentially compromise the siding’s protective layers.

- Inspection for Damage: Regularly inspect the siding for any signs of damage, such as cracks, dents, or loose panels. Addressing these issues promptly prevents further damage and maintains the structural integrity, which is vital for fire resistance.

- Caulk Repair: Inspect and repair any damaged caulk around joints and seams. Cracked or missing caulk can allow moisture to penetrate, potentially weakening the siding and compromising its fire-resistant properties.

- Painting (if applicable): If your siding is painted, repaint it as needed to maintain its protective coating. Proper painting helps to prevent deterioration and maintains the siding’s overall integrity.

Potential Issues Compromising Fire Resistance

Improper installation, such as insufficient fastening or inadequate sealing, can significantly reduce the fire resistance of siding. Furthermore, allowing excessive moisture accumulation behind the siding can create conditions conducive to mold growth and weaken the structural integrity of the wall assembly, compromising its fire resistance. Damage to the siding, such as cracks or holes, can create pathways for flames to spread.

Safety Precautions During Installation and Maintenance

- Always wear appropriate safety gear, including eye protection, gloves, and dust masks.

- Use caution when working at heights and utilize appropriate fall protection equipment.

- Follow the manufacturer’s instructions carefully.

- Use the correct tools and fasteners for the specific siding material.

- Be aware of potential hazards associated with power tools and chemicals.

- Ensure proper ventilation when working with chemicals or in confined spaces.

Cost and Sustainability Considerations

Choosing fire-resistant siding involves careful consideration of both upfront costs and long-term implications, including environmental impact. The initial investment varies significantly depending on the material selected, and ongoing maintenance needs also differ. Sustainable choices are increasingly important, demanding a balanced assessment of economic and ecological factors.

The total cost of fire-resistant siding encompasses the initial purchase price of the materials, labor costs for installation, and anticipated maintenance expenses throughout the siding’s lifespan. Long-term maintenance may include repainting, cleaning, or minor repairs, depending on the material and environmental conditions. Furthermore, the environmental impact of manufacturing, transportation, and eventual disposal of the siding must be considered when evaluating the overall sustainability of each option.

Cost Comparison of Fire-Resistant Siding Materials

A direct cost comparison is complex due to fluctuating material prices and regional variations in labor costs. However, a general overview can be provided. Fiber cement siding typically offers a mid-range initial cost, while metal siding (like steel or aluminum) can be more expensive upfront but often requires less maintenance. Certain types of engineered wood siding, treated for fire resistance, usually fall within a lower to mid-range price bracket, although their longevity might be shorter than other options.

Installation costs will vary based on the complexity of the project, the size of the house, and the installer’s rates.

Environmental Impact of Fire-Resistant Siding Materials

The environmental impact of fire-resistant siding materials varies considerably depending on the manufacturing process, material composition, and end-of-life management. For example, fiber cement siding, while durable, has a significant carbon footprint due to the energy-intensive cement production. Metal sidings, particularly those made from recycled materials, can have a lower environmental impact, but their manufacturing still involves energy consumption.

Engineered wood sidings may present a less significant carbon footprint compared to fiber cement, depending on the specific treatment and wood sourcing. The disposal of each material also carries implications; some are more easily recycled than others.

Eco-Friendly and Sustainable Options for Fire-Resistant Siding

Several strategies contribute to making fire-resistant siding more environmentally friendly. Choosing materials with high recycled content reduces the demand for virgin resources. Opting for locally sourced materials minimizes transportation emissions. Sidings with longer lifespans reduce the frequency of replacement and associated waste. Finally, selecting materials that are easily recyclable or compostable at the end of their service life contributes to a circular economy.

Life Cycle Cost and Environmental Impact Comparison

The following table provides a simplified comparison. Actual values can vary based on specific product choices, location, and installation practices. This table should be considered a general guideline, not precise figures for a particular project.

| Material | Initial Cost (Relative) | Maintenance Cost (Relative) | Environmental Impact (Relative) |

|---|---|---|---|

| Fiber Cement | Medium | Low | High |

| Metal (Steel/Aluminum) | High | Very Low | Medium |

| Engineered Wood (Fire-Treated) | Low to Medium | Low to Medium | Low to Medium |

Case Studies and Real-World Applications

Fire-resistant siding offers significant advantages in enhancing building safety and longevity. Examining real-world applications demonstrates the effectiveness and versatility of these materials across diverse building types and climates. The following case studies illustrate how the strategic selection of fire-resistant siding can significantly impact overall fire safety and building performance.

Examples of Successful Fire-Resistant Siding Implementations, FireResistant Siding Materials

Three distinct examples highlight the successful integration of fire-resistant siding in various building projects. The choice of material in each case was driven by specific project needs, including budget, aesthetic considerations, and local building codes. The performance data collected post-installation further validates the effectiveness of these choices.

- A high-rise residential building in California: This building utilized fiber cement siding due to its inherent fire resistance, durability in the California climate (withstanding strong winds and sunlight), and relatively low cost compared to other options. The building’s design incorporated large expanses of glass, making the choice of non-combustible siding crucial for overall fire safety. Post-construction inspections and simulations confirmed the siding’s effectiveness in containing fire spread.

The fiber cement’s ability to withstand extreme weather conditions, including wildfires, proved invaluable.

- A commercial warehouse in Texas: This large-scale warehouse complex opted for metal siding with a high fire-resistance rating. The primary reason for this selection was the material’s exceptional fire resistance and low maintenance requirements. Metal siding also offers durability in harsh weather conditions and its ability to withstand impacts. The warehouse’s large footprint and flammable materials stored inside necessitated a robust fire-resistant exterior to minimize risk.

- A historical building renovation in New England: This project employed a composite material siding with a fire-retardant treatment. The choice prioritized maintaining the building’s historical aesthetic while enhancing fire safety. The composite material was chosen for its ability to mimic the appearance of traditional wood siding while offering significantly improved fire resistance. The fire-retardant treatment provided an added layer of protection. This example demonstrates that fire safety can be effectively integrated into historical preservation projects without compromising architectural integrity.

Impact of Fire-Resistant Siding on Overall Fire Safety

The choice of fire-resistant siding directly influences a building’s overall fire safety profile. Non-combustible siding materials significantly reduce the risk of fire spreading from the exterior to the interior of a building. This is especially crucial in high-density areas and regions prone to wildfires. Furthermore, the use of fire-resistant siding can positively impact insurance premiums and enhance the building’s overall value by demonstrating a commitment to safety.

By slowing or preventing the spread of fire, fire-resistant siding provides valuable time for evacuation and emergency response.

Benefits of Fire-Resistant Siding in Different Building Types

The benefits of fire-resistant siding extend across diverse building types:

- Residential: Provides enhanced safety for occupants, potentially reducing insurance costs and increasing property value. Aesthetics can be matched to various architectural styles.

- Commercial: Protects valuable assets and ensures business continuity in case of fire. Reduces liability and demonstrates a commitment to safety standards.

- Industrial: Crucial in facilities handling flammable materials, minimizing risk of catastrophic fire events and protecting employees.

Ideal Fire-Resistant Siding Choices for Different Building Scenarios

Three scenarios illustrate the selection process for fire-resistant siding based on varied factors:

- Coastal residential home (high humidity, moderate budget): Fiber cement siding is a suitable choice. Its durability against moisture and relatively low cost makes it an effective and practical option.

- High-rise apartment building in a wildfire-prone area (high budget, stringent fire safety requirements): A high-performance metal panel system with a superior fire rating would be the ideal selection, offering superior protection in extreme conditions.

- Small commercial building in a temperate climate (moderate budget, emphasis on aesthetics): A composite material siding with a fire-retardant treatment might be a good choice, balancing aesthetic appeal with necessary fire protection.

FAQ Resource

What is the lifespan of fire-resistant siding?

The lifespan varies depending on the material. Metal siding can last 50 years or more, while fiber cement typically lasts 30-50 years. Proper maintenance significantly impacts longevity.

How often should fire-resistant siding be inspected?

Annual inspections are recommended to check for damage, loose fasteners, or signs of deterioration. More frequent inspections may be necessary in harsh climates.

Can I install fire-resistant siding myself?

While DIY installation is possible for some types, professional installation is generally recommended, especially for complex projects, to ensure proper fire resistance.

Are there tax incentives for using fire-resistant siding?

Tax incentives vary by location and may be available in areas with stringent fire codes or wildfire risks. Check with your local government for details.

How does fire-resistant siding impact home insurance premiums?

Insurance companies often offer discounts on premiums for homes with fire-resistant features, including siding. Contact your insurer for specific details.