Stucco Siding Installation Costs A Comprehensive Guide

Stucco Siding Installation Costs are a significant consideration for any homeowner undertaking an exterior renovation. Understanding the various factors that influence the final price is crucial for effective budgeting and project planning. From the type of stucco chosen and its associated material costs to the labor involved and regional variations in pricing, numerous elements contribute to the overall expense.

This guide delves into these intricacies, offering a clear picture of what to expect and how to navigate the process successfully.

This comprehensive guide will explore the key drivers of stucco siding installation costs, providing a detailed breakdown of material expenses, labor charges, and additional considerations. We will examine different stucco types, installation methods, and regional pricing variations, empowering you with the knowledge needed to make informed decisions throughout your project.

Factors Influencing Stucco Siding Installation Costs

Several key factors significantly impact the overall cost of stucco siding installation. Understanding these variables allows homeowners to better budget for their projects and make informed decisions during the planning process. These factors range from geographical location and project scope to material choices and regulatory requirements.

Geographic Location’s Impact on Stucco Siding Installation Prices

The cost of stucco installation varies considerably across different geographic regions. Labor rates, material availability, and local regulations all contribute to this variation. For instance, areas with a high cost of living, such as major metropolitan centers on the West Coast, tend to have higher labor costs compared to more rural areas in the Midwest. Similarly, the price of cement and other materials can fluctuate based on regional supply and demand.

Transportation costs for materials also play a role, adding to the expense in remote locations. Local building codes and permit fees can also vary significantly from one region to another, further influencing the total project cost.

Project Size and Complexity’s Influence on Overall Costs

The size and complexity of the project directly affect the overall cost. Larger projects naturally require more materials and labor, leading to higher expenses. Complex projects, such as those involving intricate designs, multiple layers of stucco, or extensive preparation work (e.g., significant repairs to the underlying structure), will also demand more time and expertise, thus increasing the cost.

A simple, single-story house with a straightforward design will cost considerably less than a multi-story building with complex architectural features requiring specialized techniques.

Labor Costs versus Material Costs in Stucco Siding Installation

Stucco installation involves a significant labor component. Labor costs typically represent a substantial portion (often 50% or more) of the total project expense. Factors influencing labor costs include the experience and skill level of the installers, the project’s complexity, and prevailing wage rates in the region. Material costs, on the other hand, are influenced by the type and quantity of stucco used, the cost of lath, wire mesh, and other necessary materials.

Accurate estimation requires careful consideration of both labor and material costs, as their proportions can vary depending on the project’s specific circumstances.

Different Stucco Types and Their Corresponding Price Ranges

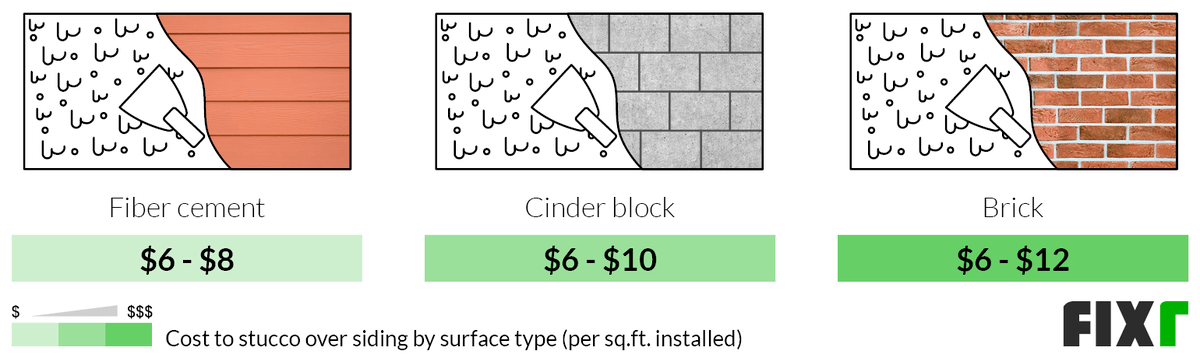

Various stucco types exist, each with different price points. Traditional cement-based stucco is generally the most affordable option. Acrylic stucco, offering improved durability and flexibility, is typically more expensive. Synthetic stucco, a more modern alternative, provides benefits like resistance to cracking and water damage, but commands a higher price. The specific price range for each type can vary based on factors such as the quality of the materials, the quantity needed, and the location.

For example, a high-end acrylic stucco might cost $8-$12 per square foot installed, while a basic cement stucco might range from $5-$8 per square foot.

Permits and Inspections’ Influence on Total Project Expense

Obtaining necessary permits and undergoing inspections adds to the total project cost. Permit fees vary based on location and the project’s scope. Inspections ensure compliance with building codes and safety standards. Delays caused by permit processing or failed inspections can also increase labor costs. It’s crucial to factor in these costs during the budgeting phase to avoid unexpected expenses.

Cost Comparison of Different Stucco Finishes

The following table compares the cost per square foot (installed) for different stucco finishes. Note that these are estimates and can vary depending on location and project specifics.

| Stucco Finish | Price Range per Square Foot (USD) | Description | Advantages |

|---|---|---|---|

| Smooth | $5 – $8 | A classic, clean look. | Easy to clean, modern appearance. |

| Textured | $6 – $9 | Offers a variety of textures, from fine to coarse. | Hides minor imperfections in the wall, durable. |

| Venetian | $10 – $15 | A highly polished, smooth finish with a marble-like appearance. | Elegant, high-end look. |

| Sand Finish | $7 – $10 | A coarse, sandy texture. | Very durable, good for hiding imperfections. |

Material Costs for Stucco Siding Installation

The cost of stucco siding installation is significantly influenced by the materials used. Understanding the price variations between different stucco types, underlayments, and color options is crucial for accurate budgeting. This section details the various material costs involved, allowing for a more informed decision-making process.

Stucco Mix Cost Variations

Different stucco mixes offer varying properties and price points. Cement-based stucco, a traditional and durable option, generally provides a cost-effective solution. However, acrylic stucco, while more expensive, boasts superior flexibility, crack resistance, and color retention. Synthetic stucco blends, combining cement and polymers, offer a balance between durability and cost. The price differences stem from the composition of the mix, the manufacturing process, and the inclusion of additives that enhance specific properties.

For example, a high-performance acrylic stucco might cost 2-3 times more than a standard cement-based mix. This price difference is often justified by its longer lifespan and reduced maintenance needs.

Lath, Wire Mesh, and Underlayment Costs

Proper underlayment is essential for a long-lasting and structurally sound stucco application. This typically involves using metal lath or wire mesh, which provides a surface for the stucco to adhere to. The cost of these materials varies based on the type, gauge, and area covered. Additional underlayments, such as a water-resistant membrane, might be necessary depending on the climate and building conditions.

These additional layers contribute to the overall project cost, acting as a critical investment in the longevity and performance of the stucco siding. For instance, using a thicker gauge wire mesh may add to the cost but also increases the strength and durability of the final product.

Stucco Color and Texture Costs

The chosen color and texture can also influence the overall material costs. Custom colors often involve adding pigments to the stucco mix, leading to a higher price compared to standard colors. Textured finishes, such as a sand-finished or a dash finish, also add to the expense, as they require additional labor and materials. The complexity of the texture directly impacts the cost.

A simple, smooth finish will generally be less expensive than a more elaborate, hand-applied texture. For example, a highly specialized Venetian plaster finish can significantly increase the overall material cost.

Pre-mixed versus On-site Mixed Stucco

Pre-mixed stucco offers convenience and consistency, but it usually comes at a higher price compared to on-site mixing. On-site mixing allows for greater control over the mix ratios and can potentially reduce material costs, but it requires skilled labor and specialized equipment. The choice between these two options depends on factors such as project scale, labor costs, and desired quality control.

For larger projects, pre-mixed stucco may be more efficient despite the higher upfront cost. For smaller projects, on-site mixing could offer cost savings.

Stucco Material Price per Square Foot

| Stucco Type | Underlayment | Color/Texture | Price per sq ft ($) |

|---|---|---|---|

| Cement-based | Metal Lath | Standard | 3-5 |

| Acrylic | Metal Lath & Water-resistant membrane | Standard | 6-9 |

| Synthetic Blend | Wire Mesh | Custom Color | 7-11 |

| Acrylic (High-Performance) | Metal Lath & Water-resistant membrane | Custom Texture | 10-15 |

Labor Costs for Stucco Siding Installation

Labor costs represent a significant portion of the overall expense for stucco siding installation. These costs are influenced by several factors, including the project’s scope, the installer’s experience, and regional variations in wages. Understanding these factors is crucial for accurate budgeting and project planning.

Labor Cost Breakdown by Project Size and Complexity

The labor cost for a stucco installation project is directly proportional to its size and complexity. Smaller projects, such as covering a single wall or a small section of a house, naturally require less labor and thus incur lower costs. Conversely, larger projects, like covering an entire house or multiple buildings, necessitate a greater workforce and extended working hours, resulting in significantly higher labor costs.

Complexity also plays a key role. Intricate designs, extensive corner detailing, or the need for specialized techniques will increase the time and skill required, ultimately impacting the labor cost. For example, a simple, one-story house with a standard stucco finish will cost considerably less in labor than a multi-story home with elaborate architectural features requiring specialized techniques like EIFS (Exterior Insulation and Finish System) installation.

Typical Hourly or Daily Rates for Stucco Installers in Different Regions

Hourly or daily rates for stucco installers vary considerably depending on geographical location. In high-cost-of-living areas such as major metropolitan centers on the coasts, skilled stucco installers may command daily rates ranging from $300 to $500 or more. In less expensive regions, daily rates might fall between $200 and $350. These rates are often influenced by factors such as union membership, the installer’s experience, and prevailing market conditions.

It is important to obtain multiple quotes from local contractors to get an accurate estimate for your specific area. For instance, a contractor in rural Nebraska might charge less per day than one working in San Francisco, California.

Factors Influencing Labor Costs

Several factors beyond project size and location significantly impact labor costs. The experience level of the installer is paramount. Highly experienced and skilled installers, possessing expertise in various techniques and capable of handling complex projects efficiently, generally command higher rates. Project urgency also plays a role; expedited projects often require overtime pay or the use of a larger crew, thereby increasing labor costs.

Furthermore, the time of year can influence labor costs. Demand during peak construction seasons can drive up rates due to increased competition for skilled labor.

Cost Implications of Specialized Techniques

Specialized techniques, such as intricate corner detailing or the incorporation of complex designs, invariably increase labor costs. These techniques require a higher level of skill and precision, demanding more time and expertise from the installers. For example, the creation of custom stucco moldings or the integration of other materials, like stone or brick, into the stucco design, significantly increases the labor component of the overall project cost.

The added complexity necessitates more meticulous work, potentially leading to a substantial increase in labor charges.

Comparison of Labor Costs for Different Installation Methods

The choice of installation method directly affects labor costs. Here’s a comparison:

- Traditional stucco installation: This method involves applying stucco in multiple coats by hand, requiring skilled labor and more time. This generally results in higher labor costs compared to spray application.

- Spray stucco installation: This method utilizes specialized equipment to apply stucco, reducing the labor intensity and time required. This generally leads to lower labor costs than traditional hand application, although the initial investment in equipment might be higher for the contractor.

Additional Costs Associated with Stucco Siding Installation: Stucco Siding Installation Costs

Beyond the material and labor costs directly involved in applying stucco, several additional expenses can significantly impact the overall project budget. Careful planning and budgeting for these ancillary costs are crucial to avoid unexpected financial burdens during the project. Understanding these potential additions allows for a more accurate cost projection and smoother project execution.

Site Preparation and Cleanup Costs

Site preparation is essential for a successful stucco installation. This involves tasks such as clearing the area around the house, removing debris and vegetation, and preparing the surface of the walls. Cleanup after installation includes disposing of construction waste, such as leftover stucco, packaging materials, and debris generated during the process. The cost of site preparation and cleanup can vary depending on the size of the house and the extent of the preparation needed.

For example, a large house with extensive landscaping might require more extensive preparation and, consequently, higher costs. Similarly, areas with significant debris will increase disposal expenses. Expect to budget several hundred to a few thousand dollars for these tasks, depending on the project’s scope.

Scaffolding, Equipment Rentals, and Waste Disposal Expenses

Scaffolding is often necessary for safe and efficient stucco application, especially on taller buildings. The cost of scaffolding rental depends on the height of the building and the duration of the project. Other equipment rentals might include tools like mixers, hoists, and power washers. Waste disposal costs are influenced by the volume and type of waste generated. Proper disposal of construction waste is crucial for environmental compliance.

In some areas, special permits or fees may be required for waste disposal, particularly for hazardous materials. A typical project might involve several hundred to a thousand dollars in equipment rental and waste disposal costs, potentially more for larger projects or those requiring specialized equipment.

Repair and Maintenance Costs After Installation

While stucco is a durable material, repairs and maintenance may be needed over time. Cracks, chips, or water damage can occur due to various factors, including settling of the foundation, extreme weather conditions, or improper installation. These repairs can range from minor patching to more extensive work, impacting the long-term cost of ownership. Regular maintenance, such as cleaning and sealing, can help prevent more significant problems and reduce long-term costs.

Budgeting for potential repairs and maintenance, even if they are not immediately anticipated, is a prudent approach. Costs can vary greatly depending on the extent of the damage, ranging from a few hundred dollars for minor repairs to several thousand for extensive work.

Potential Hidden Costs

Unexpected issues can arise during stucco installation, leading to hidden costs. For example, discovering rotted wood or damaged sheathing behind the existing siding requires additional repair work before stucco can be applied. Unforeseen problems with the existing wall structure may also necessitate costly repairs. It’s wise to include a contingency buffer in the budget to accommodate these possibilities.

This contingency could be 10-20% of the initial estimated cost, depending on the age and condition of the house.

Warranties and Insurance Costs

Many contractors offer warranties on their stucco installation work, covering defects in materials or workmanship. The cost of these warranties can vary depending on the length of coverage and the contractor’s policy. Additionally, the contractor’s liability insurance protects against potential accidents or damages during the installation process. While these costs are typically included in the overall contract price, it’s vital to clarify the specifics of the warranty and insurance coverage to understand the level of protection provided.

Estimating and Budgeting for Stucco Siding Installation

Accurately estimating and budgeting for stucco siding installation is crucial for a smooth and financially responsible project. Underestimating costs can lead to project delays and financial strain, while overestimating can result in unnecessary spending. A well-planned budget, based on realistic cost estimates, protects homeowners from unforeseen expenses and ensures a successful project completion.

Calculating a Realistic Budget for Stucco Siding Installation, Stucco Siding Installation Costs

Developing a realistic budget requires a systematic approach, combining accurate cost estimations with a contingency plan. This involves gathering detailed information about your project’s scope and factoring in all potential expenses. Begin by determining the square footage of the area to be covered with stucco. Next, obtain detailed quotes from multiple contractors, breaking down the costs into material and labor components.

Finally, add a contingency buffer to account for unexpected issues or price fluctuations. For example, a 1500 square foot home requiring stucco installation might require a budget of $15,000 – $25,000 depending on the complexity of the project and material choices. This range accounts for variations in labor rates and material costs across different regions and contractors.

Obtaining Accurate Estimates from Contractors

Securing accurate estimates requires meticulous preparation and careful contractor selection. Provide contractors with detailed plans and specifications, including measurements, desired materials, and any special features. Request itemized estimates that clearly separate material and labor costs. Compare multiple bids to identify any discrepancies and ensure you understand the scope of work included in each quote. Consider the contractor’s experience, reputation, and licensing.

Checking online reviews and references can help you choose a reliable and trustworthy contractor.

Negotiating Prices and Securing Favorable Terms

Once you’ve received multiple estimates, you can begin the negotiation process. Focus on the itemized breakdown of costs to identify areas where savings might be possible. For example, you might negotiate on the type of stucco or the labor rate. Be respectful and professional during negotiations, emphasizing your budget constraints while acknowledging the contractor’s expertise and costs.

Negotiate payment terms that suit your financial capabilities, perhaps proposing a staged payment schedule. Always secure a written contract that clearly Artikels all agreed-upon terms, including payment schedules, timelines, and warranties.

Considering Contingency Funds for Unforeseen Expenses

Unforeseen expenses are common in construction projects. Unexpected issues like hidden damage, material shortages, or weather delays can significantly impact the budget. To mitigate these risks, allocate a contingency fund of 10-20% of the total estimated cost. This fund acts as a buffer to cover unforeseen expenses, preventing project delays and financial stress. For example, if your estimated cost is $20,000, a 15% contingency fund would be $3,000.

This provides a safety net for potential complications.

Sample Budget Template for Stucco Siding Installation

A well-structured budget template helps organize your finances and track expenses. Here’s a sample template:

- Project: Stucco Siding Installation

- Total Square Footage: [Insert Square Footage]

- Material Costs:

- Stucco: $[Amount]

- Lath: $[Amount]

- Mesh: $[Amount]

- Accessories (fasteners, etc.): $[Amount]

- Subtotal Material Costs: $[Sum of Material Costs]

- Labor Costs: $[Amount]

- Permits and Inspections: $[Amount]

- Contingency Fund (10-20%): $[Amount]

- Total Estimated Cost: $[Sum of all costs]

Visual Representations of Stucco Siding Installation

Understanding the visual aspects of stucco installation is crucial for homeowners to manage expectations and appreciate the final product. The process involves a series of transformations, from a bare wall to a finished, textured surface, significantly impacting the home’s aesthetic appeal. This section details these visual changes throughout the installation process, showcasing the differences between various stucco types and the impact of color and pattern choices.

Stucco Application: A Step-by-Step Visual Transformation

The visual journey of stucco application begins with a bare wall, possibly showing imperfections or previous siding. The first step involves preparing the wall surface. This might involve cleaning, repairing cracks or holes, and applying a waterproof membrane, which remains largely unseen but provides a crucial foundation. Next, the lath system (metal or wire mesh) is installed, providing a framework for the stucco.

This stage creates a textured, slightly uneven surface, visually distinct from the smooth initial wall. The first coat, or scratch coat, is then applied, creating a rough, uneven surface. This coat is intentionally rough to provide a better bond for the subsequent layers. Visually, the wall now appears textured and noticeably thicker. The second coat, or brown coat, is smoother and fills in many of the imperfections from the scratch coat.

This coat provides a more even base for the final finish coat. The final, or finish coat, is applied, offering the desired texture and color. At this stage, the visual transformation is complete, with the wall showcasing the chosen stucco finish and color. The final product will be smooth or textured, depending on the finish applied, and should exhibit a uniform color and texture across the surface.

Visual Differences Between Stucco Finishes and Textures

Different stucco finishes create vastly different visual effects. A smooth finish presents a clean, modern look, ideal for contemporary homes. In contrast, a textured finish, such as a “dash” finish, offers a more rustic or traditional appearance with a pebbled texture. A “sand” finish provides a slightly coarser texture than a dash finish, while a “exposed aggregate” finish showcases the small stones within the stucco mix, providing a more rugged and natural appearance.

These varied textures add depth and visual interest, significantly impacting the overall aesthetic. For example, a smooth stucco finish might be chosen for a minimalist home design, while a textured finish might complement a more traditional architectural style. The visual differences are quite striking, with each finish offering a unique character and feel.

Visual Impact of Color and Pattern in Stucco Siding

Color and pattern choices significantly impact a home’s exterior visual appeal. Light colors, such as whites and creams, create a sense of spaciousness and brightness, making the home appear larger and more welcoming. Darker colors, such as deep blues or grays, provide a more dramatic and sophisticated look, adding depth and visual weight. The use of contrasting colors or patterns can create visual interest and highlight architectural details.

For instance, using a darker color for the trim or around windows and doors can accentuate these features. Moreover, patterns, such as those achieved through the application of different textures or colors in a specific arrangement, can add a unique and personalized touch. Consider a home with light-colored stucco and darker accents around the windows and door frames; this creates a visual focal point and enhances the overall aesthetic.

The strategic use of color and pattern can dramatically transform the appearance of a home, showcasing personal style and enhancing curb appeal.

FAQ Section

What is the average lifespan of stucco siding?

With proper installation and maintenance, stucco siding can last 50 years or more.

Can I install stucco siding myself?

While possible for smaller projects, professional installation is generally recommended for optimal results and warranty coverage. Stucco application requires specialized skills and techniques.

What are the best ways to maintain stucco siding?

Regular cleaning to remove dirt and debris, prompt repair of any cracks or damage, and periodic painting or sealing are crucial for maintaining stucco siding.

Are there any environmental considerations for stucco siding?

Some stucco mixes have lower environmental impact than others. Consider the embodied carbon of the materials and the potential for sustainable sourcing.

How long does stucco siding installation typically take?

The duration varies greatly depending on project size and complexity, ranging from a few days to several weeks.